In this study, the Eindhoven University (TU/e) and the Dutch Organization for Applied Scientific Research ( TNO) investigated the use of atmospheric plasma-enhanced spatial ALD (PE-s-ALD) for the growth of titanium oxide (TiOx) in planar and 3D substrates. Overall, this work shows that though highly conformal deposition of TiO2 is possible, detailed understanding of the interplay of growth mechanisms that govern TiO2 deposition is essential to control conformality in terms of both thickness and film properties.

Authors

Mike van de Poll, Jie Shen, James Hilfiker, Marcel Verheijen, Paul Poodt, Fieke van den Bruele, Wilhelmus Kessels en Bart Macco*

Plasma-Enhanced Spatial Atomic Layer Deposition on 2D and 3D Surface Topologies: The Case of Amorphous and Crystalline TiO2

Abstract

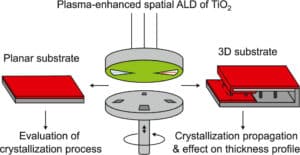

Plasma-enhanced spatial ALD (PE-s-ALD) is an interesting technique for high-volume manufacturing of thin films at low-temperature. This technique is particularly appealing for conformal depositions on 3D surfaces for various applications, such as optical coatings, electrolyzers, and batteries. However, various crystallization and growth effects can influence the final film profile and properties, and understanding these effects and their interplay is key. This study investigates the complex growth mechanism of TiO2 using PE-s-ALD. TiO2 films are deposited on both planar and 3D substrates, while systematically varying the number of cycles, deposition temperature, and exposure times. Thickness, crystallinity, and composition are determined as a function of depth inside the structures. Conditions that result in the anatase phase on a planar surface only partially form this phase inside 3D structures, with the deepest part of the film being amorphous. This partial crystallization is ascribed to the film thickness inside the 3D structure gradually dropping below the critical thickness for crystallization. In turn, the partial crystallization is shown to have a significant effect on the resulting thickness profile, due to a difference in growth per cycle between the two phases. A framework of the interplay between effects is proposed, offering insights that enable better control of crystallinity and thickness throughout the entirety of coated surfaces of 3D structures by PE-s-ALD. Additionally, the recombination probability of oxygen radicals during this atmospheric-pressure PE-s-ALD process at 200 °C is determined to be 3 × 10–5. This value is similar to low-pressure PE-ALD, indicating that differences in conformality between the two types of ALD are not the result of differences in recombination probability, but rather of differences in initial radical density and diffusion behavior.

Figure of Plasma-enhanced Spatial ALD of TiO2

Copyright © 2025 The Authors. Published by American Chemical Society.

Read the whole article published in the Journal of Physical Chemistry C here.

About SparkNano & spatial ALD & plasma-enhancement

SparkNano develops and supplies spatial Atomic Layer Deposition equipment for next gen applications in green hydrogen, batteries, solar, display and more. SparkNano was first founded in 2018 as a spin-off of TNO (the Netherlands Organization of Applied Scientific Research). The company’s products enable its customers to seamlessly scale from lab-to-fab. Next to the high-quality equipment, an experienced team also supports in process development and optimization, provides application support and yield and performance management. SparkNano is located in the Brainport ecosystem in Eindhoven, the Netherlands.

Chief Technology Officer

Learn more about spatial ALD

Are you interested to learn how plasma-enhanced spatial ALD can help your innovation? Schedule a meeting with our team to learn more about our unique spatial ALD technology and state-of-the-art product portfolio.